As we all know, injector valve assembly play an important role in injector. if there is a problem with the injector valve assembly, it will cause the entire injector and engine to run improperly, thus affecting the operation of the car. It is therefore necessary to check and replace the injector valve assembly in time. The following are the conditions for replacing the injector valve assembly:

Injector Valve Assembly’s Introduction

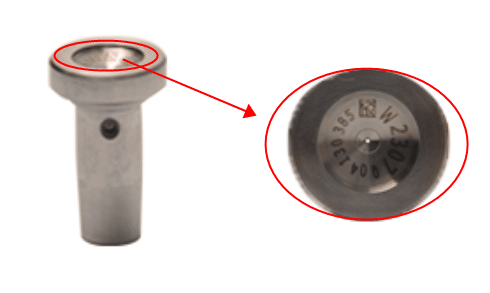

Injector valve assembly is consisted of valve rod and valve cap, installed in the controlling room in the house body of injector. The main function of injector valve assembly is to control oil injection and oil return. Injector valve assembly is one of the most core components, also one of parts with the highest damage rate.

Valve cap

When checking the valve cap, you need to use microscope to observe the contact surface between the valve cap and the ball to see whether the valve cap is damaged or not, if there is damage, the valve cap must be replaced.

Valve rod

Check the top of valve rod which has contact with valve cap, if the valve rod has damage on the surface, its original silver color turns into white, the valve rod needs to be replaced.

Check the valve rod’s contact part with injector, if the valve rod has damage on the surface, its original silver color turns into white, the valve rod needs to be replaced.

Details of Replacement Conditions

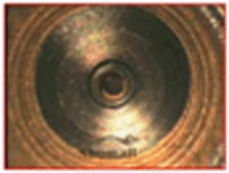

Valve Cap

Under the microscope, magnify 20 times to check that the oil inlet hole of the valve cap and the oil return hole of the bonnet are not worn, grooved, scratched, damaged, rusted or dented.

The wear of the top oil return hole causes the oil return to be too large and the leaking injector cannot inject oil.

The side inlet hole is blocked causing the injector to establish the pressure chamber and the injector to function normally.

Wear of the cap cavity can cause the injector to work properly when the injector is badly delayed.

Valve Rod

Microscope amplification 20 times, check the valve rod for wear, not smooth surface color, rust.

The excessive clearance between the stem wear and the housing and between the cap causes an injector delay

The valve stem lag will cause the injector to start the solenoid to start, and the oil needle can not return quickly after the nozzle is opened

Check the injector components before replacing the injector valve assembly according following the injector service manual to avoid further damage to the injector valve assembly.

|

|

|

| The valve stem is worn out and needs to be replaced | The valve stem surface is not smooth and colorless, and it needs to be replaced | The valve stem is rusty and needs to be replaced |

For further information of injector valve set, please check:

injector valve set product details:

https://dieselcontrolvalveset.com/product/

injector valve set technical file:

https://dieselcontrolvalveset.com/download/

injector valve set video:

https://dieselcontrolvalveset.com/videos/

injector valve set encyclopedia:

https://dieselcontrolvalveset.com/category/news/encyclopedia/

injector valve set blog:

https://dieselcontrolvalveset.com/category/news/blog/

injector valve set new:

https://dieselcontrolvalveset.com/category/news/product-news/

Also you can contact us for more products’ purchase details.